Working closely with Cadent and partners

A complete turnkey service

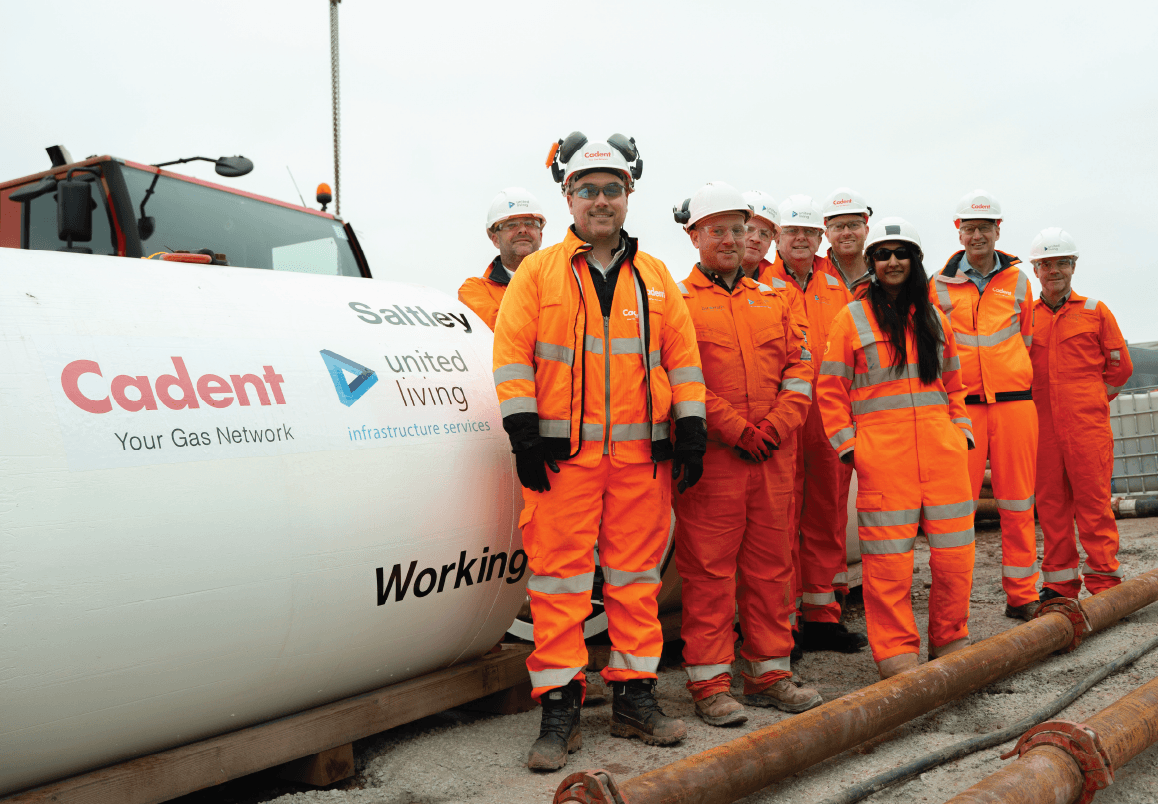

To facilitate the construction of a major transport infrastructure project and ensure a safe and reliable gas supply, Cadent appointed United Infrastructure to deliver a complex gas pipeline diversion at Saltley Viaduct in Birmingham. The project commenced in August 2024 and was completed by March 2025 under the NEC Option A form of contract.

This development required the diversion of an existing 450mm Intermediate pressure gas pipeline to accommodate the new viaduct. The project involved the rerouting of 260 metres of pipeline, including an Under Track Crossing (UTX) beneath existing railway lines.

The project required extensive stakeholder engagement, with a record number of consents obtained for a Cadent project. Despite a stringent timeline, UI delivered the project ahead of schedule and within budget.